Food & Beverage (F&B) is an important revenue driver in hotels and naturally investing in kitchens that are efficient and effective can make or break the food deal for hoteliers.

How many times do you step into a hotel because you like the food there? Chances are several times if not always. Hotels are uniquely positioned to prepare and present food like no other thanks to the fact that they have access to sophisticated equipments and cutting edge kitchens. It is then very important that the design of the kitchen is done in a manner to maximize its effectiveness and make space for equipments that give the hotel a cutting edge.

Innovation Matters

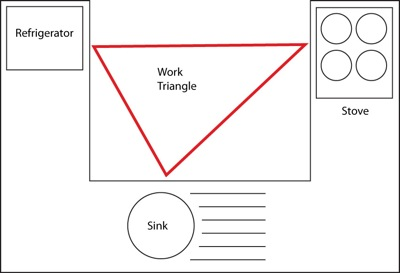

Innovation in industrial kitchens works hand in hand with increasing the efficiency of the space and manpower provided. “This also translates into “Kitchen work Triangle” which says that distance between cooking range, sink and refrigerator should be minimal so as to increase the efficiency of the person working in that area,” said Chef Sahil Arora, Executive Chef, Renaissance Mumbai Convention Centre Hotel and Marriott Executive Apartments, Mumbai. “Kitchen Triangle” is a way to design kitchen so as to increase the maximum efficiency from a staff working in the kitchen. The “Kitchen Triangle” is a layout of cooking range, hand wash sink and refrigerator in such a way that a chef cooking in an area has to travel minimum distance so as to execute his cooking operation thus saving time, energy and increasing efficiency.

Since the kitchens are occupying the space in the restaurants and have moved from heart of the house they have been camouflaged to be part of restaurant décor additionally an open kitchen in a restaurant adds to the theatrical value of the restaurant where people see their food being flamed, tossed and smoked. “Our restaurant kitchen design at Vedge is more focused on efficient working giving equal and balance space between different kitchen sections. We are focusing more on space and efficiency to dish out high quality food for almost 100 covers in one go. Importantly, we are not using expensive equipments or materials but reasonable/cost-effective equipments, which are easier to work with for all our kitchen chefs. Besides, we can also mention we have different sections for all our primary cuisines, which makes it more efficient for all chefs to dish out high quality food in a short span of time,” said Aditya Sawant, Founder and Director – Vedge.

Maximizing Space

Planning plays an important role in kitchen design. Placements of various zones wet area/cooking area keeping in mind the services available, provision of fresh air supply and exhaust are a few things involved during the planning stage. “The meetings and discussions with the hotel staff is arranged in such a way that there are points noted along with a couple of brainstorming sessions where the common points are narrowed down and priority to practicality in design is given first preference. Based on the given suggestions solutions are derived keeping in mind the practicality during operations,” said Nishant Desai of Umesh Desai and Associates Naturally then a key lies in making the most of the space. Line cooks who work on ground zero are the best people to give feedback with regards to how much design and layout of kitchen increase their efficiency and productivity. There would be times when an Executive chef will not be able to gauge the layout of certain kitchen equipment but a line cook would have a lot to say about where to place that equipment so as to increase the output of an individual. Once the kitchen layout is designed, the same is discussed with the chefs working in that area. There would be instances when some great ideas would come in and would be built up in the kitchen lay out design. “A very interesting suggestion came from one of the associates that the griller and salamander which is generally the part of pantry section of kitchen to be moved to hot kitchen as the heat emitting out of these equipments make the pantry section warm which is generally a cold section,” explained Arora.

Cost Efficiencies

Another aspect when it comes to kitchen design is the use of strategies and solutions that are incorporated to ensure reduction in the overall cost while designing kitchens. A study says that majority of the commercial spaces designed lack completely installed control systems, excessive chilling or heating capacity, and an inability to obtain the data needed to let the decision makers understand how a space is really performing. Natural light plays a major role in an industrial kitchen, the kitchen should be designed in such a way that maximum natural day light can be used to light the space. “One of the key things to keep in mind while designing the kitchen is that in case natural gas is available then most of the equipment to be installed should be compatible with natural gas and not electricity as its more expensive then gas,” avered Arora. “In order to reduce the overall cost, we try and set up all the kitchens in the same floor as far as possible. Other strategies like locating the kitchen adjacent to the banquet hall help us in keeping the cost of operation in check. We save on set up cost and benefit from easy cross functionality of the equipments. While designing cost-effective kitchens, we conduct thorough R&D about the latest products available in the market and devise our strategies accordingly,” explained Sonica Malhotra, Joint Managing Director, MBD Group. Having the kitchen in the same floor to save the maximum space and common walk-in chillers or double door walk-in chillers increases efficiency and save cost. “When there is a space concern for the commissary and Indian kitchen walk-in, we made common walk-in chiller between both the kitchens and had doors made on both the sides while keeping maintaining the size of single walk-in chiller. It had a great impact on the costs saved and helped manage operations efficiency. Another one we made a hot food counter top (OHS) with under-the-counter chiller along with a wash unit which was utilized for the all three operations (Cold storing/ keeping food hot after prepared/ cleaning utensil) added Mahesh Padala, Executive Chef, Bengaluru Marriott Hotel Whitefield.

Quality Rules

A key balancing aspect while designing cost efficient kitchens is that of quality which is the one aspect no hotel would like to compromise. A well-designed kitchen is the key to the success for any food and beverage industry. “We insure this by firstly, working with the right supplier/vendor who understands our vision for the kitchen design process and who does not compromise on the quality while retaining the right quality overall. We also do our in-depth research regarding the material (SS Steel 304 / 204) he will be using to design our kitchen and where he will be using and he procures his SS Steel and from where. Lastly, we also do reference checks with their previous clients or any projects done nearby by visiting them,” said Sawant.

Supplier Talk

The criteria for choosing vendors is on the basis of what equipment is required and who specializes in making it and how are the after sale services. Amit Roy, Partner – Thinktanc, an F&B consultancy opined “we do customised solutions in terms of designs and planning and for this we customise and make the equipment for the same. Every project we have designed has a unique theme. The client and the architect is briefed and explained how it is both aesthetic and more importantly functional. Both food and beverage and customized keeping the taste and the research process in mind. We do trials and re trials for both until its perfect in taste and in execution keeping the most important aspect of delivery time to the table. Many of the food and beverages served in our outlets are also customized and custom designed to meet both feasibility and functionality and are out of the box.”

Going Green

With increased awareness of depletion of environment by harmful business practices, the way moving forward is sustainability and usage of such products which help in reduction of carbon footprint and minimizing wastages. “One of the best practices is segregating the garbage and collecting the wet garbage area at or below 5 degree Celsius. Also, no usage of plastic and avoiding the use of too many high pressure gas ranges helps save LPG, which is a fossil fuel,” said Padala. The best type of stove to use in a commercial kitchen is a gas stove. It is much more efficient concerning carbon emissions and in distribution of heat to food (Conger). Also, if a gas stove uses an electric ignition rather than a pilot light it can reduce energy use up to 40%. “We have tried using steam generated equipments in hotel kitchens wherever possible to save the consumption of electricity,” added Desai.

Trend Check

The concept of open kitchen is an emerging trend which enables visibility and educates the guests about the entire preparation process and at the same time showcase the hygiene factor. The trend is still in an evolving phase and new additions are made every year on the features. The kitchens have taken a prime spot in restaurants and impart a new vibrant look to them and also add lot of transparency for the customers to as how their food is being cooked. Open kitchens, live cooking stations in restaurants is most trending and makes a big difference to make the restaurant successful. The new trend is designing a live kitchen. Well it is show time so get set for a gastronomical journey like no other.

This story appeared in the August 2017 issue of Hotelier India here: Kitchen Story Aug 2017