A chocolate tour is the best way to understand what goes into making arguably one of the most loved of all foods. And at Pondicherry Mason and Co does just that with an organic twist.

“Chocolate is the first luxury. It has so many things wrapped up in it: Deliciousness in the moment, childhood memories and that grin-inducing feeling of getting a reward for being good” ~ Mariska Hargitay.

Looking Back

Mason & Co was founded by Jane Mason and Fabien Bontems close to five years ago. When they came to India, Jane a trained vegan raw chef, realised that it was very hard to find good quality dark chocolate here. She soon discovered that there was cacao being grown in India and soon started using them to make chocolates at home. A Mumbai based friend happened to taste the chocolates and asked Jane to package them to retail in her store. Soon the chocolates became such a big hit that the couple decided to start Mason & Co. The main reason the chocolate tastes so good is that the company only works with certified organic farmers. There are three important steps that happen on these farms (mainly in Tamil Nadu and Kerala) that impact the eventual taste of the chocolate. This includes the actual harvesting process where the ripest cacao beans are selected. The next step is fermentation when the harvested beans are removed from the pods and are placed in wooden boxes for a week which develops the flavour. The beans ferment in their own juices. The beans are then sun dried and packed in jute sacks to be shipped to the chocolate factory. The farmers the company works with farmers and explains the kind of processing required and consults with them rather than actually owning the farms. This being a bean to bar company, they buy the cacao beans from the farmers as opposed to many other chocolate makers who buy the cacao powder.

The Tour

The tour starts at the factory where the next set of processes happen post receiving the raw cacao beans. The first step in the factory is sorting and grading the beans that are done by hand. The small beans and the ones that are stuck cannot be used to make chocolate but is sent to local farms to be used as fertilizers as the factory believes in minimising waste. Once the right beans are selected they are slow roasted in a machine that develops the flavour and sterilise the beans. This is similar to a coffee roaster and once roasted they are cooled on a tray and are not touched by hand. This is followed by a process of cracking and winnowing when the beans are cracked open using a machine and the beans are broken into smaller pieces which are then winnowed to help separate the beans and the nibs. The shells are used to make the Chocolate Herbal Tea that smells like a hot chocolate and is a specialty here. After this there is another hand process where the women at the factory separate the nibs. The nib is what is used to make the chocolates and along with organic cane sugar it is added to granite grinders. The granite stones crack the cell wall of the beans, release cacao butter that results in a paste. The chocolate is in the grinder for 3-5 days and a rich chocolate liquor is the final result. The cacao beans are 50% mass (the brown) and 50% fat (the cacao butter). The grinding process develops flavour and fineness of the chocolate. The cacao butter is added back into the chocolate and no other emulsifiers are actually used to soften the chocolate. This chocolate liquor is allowed to age further to develop flavour and is then tempered by hand. Tempering is an important process that actually gives the chocolate the shine and snap. After the chocolate is cooled it is set in the polycarbonate moulds, kept in the refrigerator for 10 minutes and is hand wrapped and packed in the boxes. This happens in the cooler section of the factory where the temperature is correctly monitored.

Making the Difference

The chocolates at Mason and Co are single origin which means that the origin is from one particular place. Each batch of chocolate can be traced back to the farmer so the company is also a single estate company so that they can stay true to the origin of the bean. Again in artisanal chocolates, the difference in taste largely comes from the bean, how it is processed and it is these subtleties that is sought to be discovered. Being an organic company, only organic cacao beans directly traded with the farmer and it tastes better. The female run factory is led by Saraswati who is the manager of the factory and was trained by Jane. Saraswati has in turn trained the other women who work here. The chocolates are naturally vegan as no dairy is used in the process. Interestingly you will also find a special coffee bar that feels like eating an expresso using a coffee bean from Blue Tokai and cacao butter. The tour lasts about two hours including a tasting session and is one of the best ways to spend an insightful time in Pondicherry. With its heart in the right place, these chocolates reflect that very ethos in their taste.

Good to know

- The cacao nib is like a superfood, high in antioxidants and used as a topping on smoothies or a trail bowl.

- Chocolate melts at 27 degrees so you can store it at lower temperatures to maintain its form.

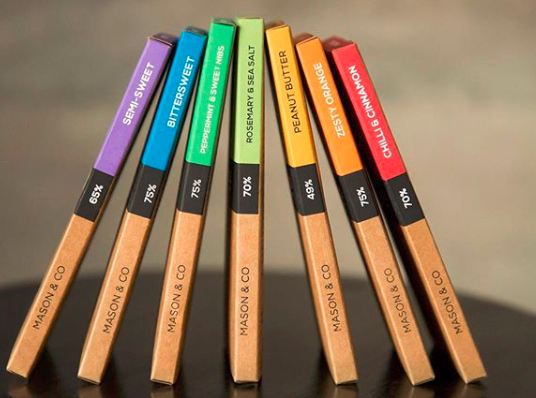

- The percentage of chocolate shows you the percentage of cacao in the bar so 75% means that is the amount of cacao.

- The key to eating dark chocolate is not to bite it, rather let it melt in your mouth.

- Some of the unique flavours include Black sesame and rasin as well as Rosemary and sea salt.

- Sign up for the chocolate tours on https://www.masonchocolate.com/events/

This story first appeared in the Nov 2018 issue of Spicejet’s Spice Route here: 164 Bean to Bar

All pics in this post are courtesy Mason & Co