Automating Apparel

The apparel industry needs several kinds of machinery to ensure that the final product is wearable. A recent development from the Government has given the much needed impetus to the apparel industry. The Cabinet, on June 22nd 2016 cleared a Rs 6,000-crore incentive package for the textiles and apparel sector to create one crore new jobs over the next three years and attract investments worth $11 billion and generating $30 billion in exports. Apparel industry body Apparel Export Promotion Council (AEPC) is expecting around Rs 5,000 crore fresh investments into the sector during the current fiscal which may create as many as two million jobs. One such organisation is the Ramsons Group founded under the auspices of the Late Ramchand Belani that has been in existence for over 50 years in Bengaluru. Sunder Belani heads the Ramsons Group which thrives on innovation. He is driven by the vision of producing international quality equipment and providing Indian consumers with an indigenous option to all their equipment needs.

Machine Matters

Ramsons’ vast product range is used in every aspect of apparel production. The equipments we manufacture are used to store, inspect, cut and count fabric. We specialize in laundry, dyeing and fining equipments for garments. We are an IBR certified supplier of steam generation equipments. These equipments perfectly complement the Steam Pressing Equipments that we are renowned for. The Vertostar™ series of textile processing equipments are prevalent in every apparel exporter’s laundry. The apparel machinery portfolio includes Steam Presses, Vacuum Ironing Systems, Body-Presses-form-finishers, Steam Generators, Value Added Machines, Co Related Machines, Material Handling Work Aids and Textile Processing Equipments. Ramsons caters to the ready to wear apparel sector and creates the most precisely engineered products at its four production facilities in and around Bengaluru, working under the most stringent quality standards and using state of the art equipment. With some of India’s leading companies as our suppliers, strong engineering talent and stringent quality control systems, they manufacture high quality products that are exported globally. Speaking on the sidelines of the dual celebration of 60 years of M/s. Veit Gmbh Germany and over 20 years of Ramsons Veit, Sunder Belani, Director, says, “we started as a small workshop and I joined the company on the 1980’s and we started making steam ironing systems as these were being imported. With that came the need for mini steam generators, fabric checking machine, stain removing machine and we soon became the largest supplier of apparel related machinery. In fact there was a time in the 1990’s sewing machine companies also approached us to manufacture machines. We have always been into manufacturing rather than trading. Our philosophy has always been to get European knowledge into India, Make in India and then export to the world. Today we make the entre gambit of machines for the apparel industry and are a one stop shop with our portfolio of 70 different machines. These start right from storage racks, material handling, steam pressing, washing machines and garment dyeing machines. We make capacities ranging from 5 kgs to 500 kgs and also since washing is a huge need we focus extensively on washing – especially denim finishes.”

Collaboration Matters

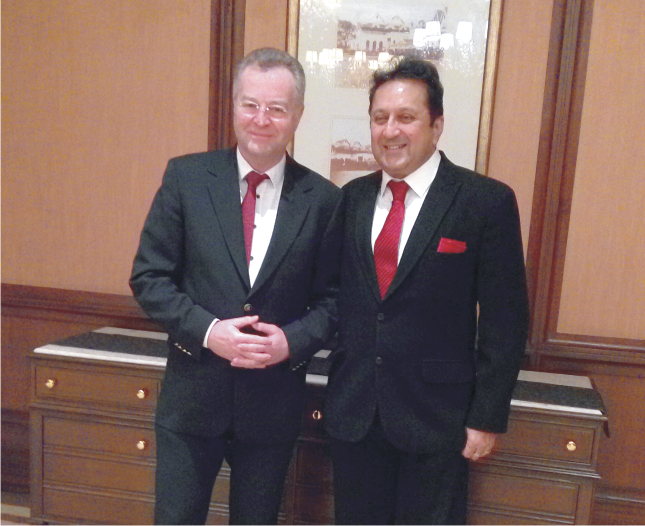

Ramsons-VEIT, Bangalore, India was founded in 1995 as collaboration between Ramsons and German based Veit group. “We decided to partner together to manufacture steam iron systems and what we cannot make here if the technology is very advanced, we import from Germany and are the agents for them here. But the association has grown well together and we are more like family now,” says Sunder. Gunter Veit, President, VEIT Group Intl., adds, “we work in four different technologies – fusing, ironing, finishing (a new technology that does not use ironing) and pressing and have 270 machines in these four categories. So basically we shape fabrics, we bring wanted creases in and take unwanted creases out and give the garment a stable form. It’s been 20 years since we have had this joint venture with Ramsons and it has worked well for us. Of course when we started the majority of the market was very basic as this is a price conscious market that makes it difficult to convince factory owners to make investments in technology.”

The Indian Market

A recent BCG report said that the textile and apparel sector can triple in size to $150 billion and create 50 million jobs by 2025. The study estimates that the industry can triple in size over the next 10 years, get $150 billion annually in foreign exchange and spur the apparel, made-ups and textile industry to reach $300 billion by 2025. The domestic market will grow at least 2.5 times to around $150 billion in size, it said, adding that since China is no longer a cheap market for manufacturers and this can create a potential market of over $280 billion for other countries. However what is the need of the hour is adapting to the right technology. “India is still far behind in terms of technological advancements even as compared to say Vietnam. However India is a big market in terms of growth as the domestic market is also huge. India is growing at a fast pace and becomes more wealthy in a way so people have more disposable income which they will spend on clothing. So for a garment machine maker being present in India is an important strategic decision. However I feel the social hierarchy in India can cause wrong decisions to be made as the boss makes the decisions without consulting anyone at the shop floor,” explains Gunter. Again India is competing with countries where labour is cheap like Ethiopia and Bangladesh, Cambodia so there is a need to make India competitive. “So we started automatic form finish machines that do not depend on manpower and increases productivity,” says Sunder.

Go Green

These machines are also being designed to be ecologically sensitive. You can reduce your energy cost by up to 40 per cent with our VEIT eMotion series. “The big new trend is energy conservation. As a single machine the fusing machine consumes a lot of energy except for say a large steam boiler. We have managed to be the pioneer in energy conservation as it is a big thrust in our product design and has been effectively implemented in the fusing machines. Ever since the 1980s, we have been pioneers in developing and manufacturing energy-efficient ironing systems. We continually set trends with our VEIT cold ironing technology with energy consumption reduced by up to 60 per cent as against heated ironing tables,” says Gunter. In fact the fusion machines are very important as the clothes cannot be finished without this machine. “In the washing area, for 1 kg of garments we used 20 litres of water but now we have got it down to 2 litres of water. Now that means the chemicals and power required has also reduced, the space required is less and we can reduce effluents. This reduces carbon foot print and also by using better motors and systems that save energy. The exhaust level of our machines like in our stumble dryer where hot air is going out, we put meshes that reduce this going out and that also helps keeping the air clean.” This apart, the recent announcement by the Government to give huge capital subsidies upto 25% for investing in equipment and garment workers will receive a 7% PF contribution which is a huge impetus. However Free Trade Agreements with foreign countries will aid the industry in further employment.

All images from http://www.ramsonsindia.com

This story appeared in the September 2016 issue of Apparel – read it here: Apparel – September 2016 – Promo – Automating Apparel